What Causes Filament Leaks

Is Your Hotend Leaking?

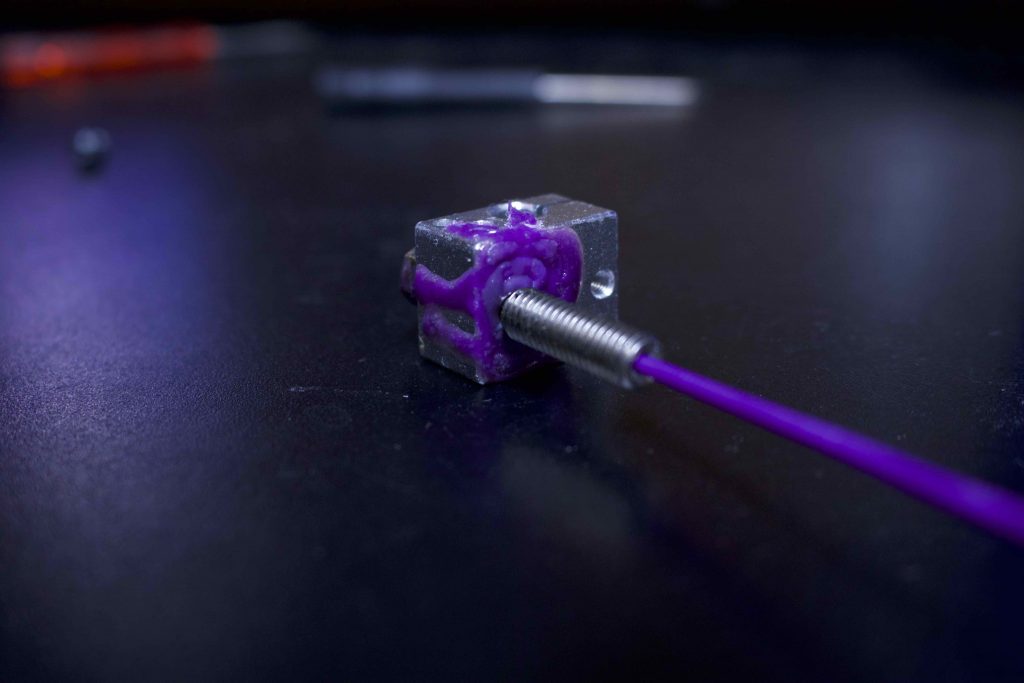

3D Printers, and their users, depend on a reliable hot end for quality prints. There are many ways a hot end can cause issues and endless tinkering. One of the most common issues 3D printer users experience is a hot end that leaks. This happens when melted filament leaks from the hot end instead of just exiting the nozzle.

This is a very frustrating experience and can cause ruined prints when the excess melted PLA or other filament material drips onto the bed area and the print itself. The best way to avoid this all-too-common problem is to select a hot end with the least potential for leaks.

Google has About 6,280,000 results listed for the search term "filament leaks"

The Leakage Problem

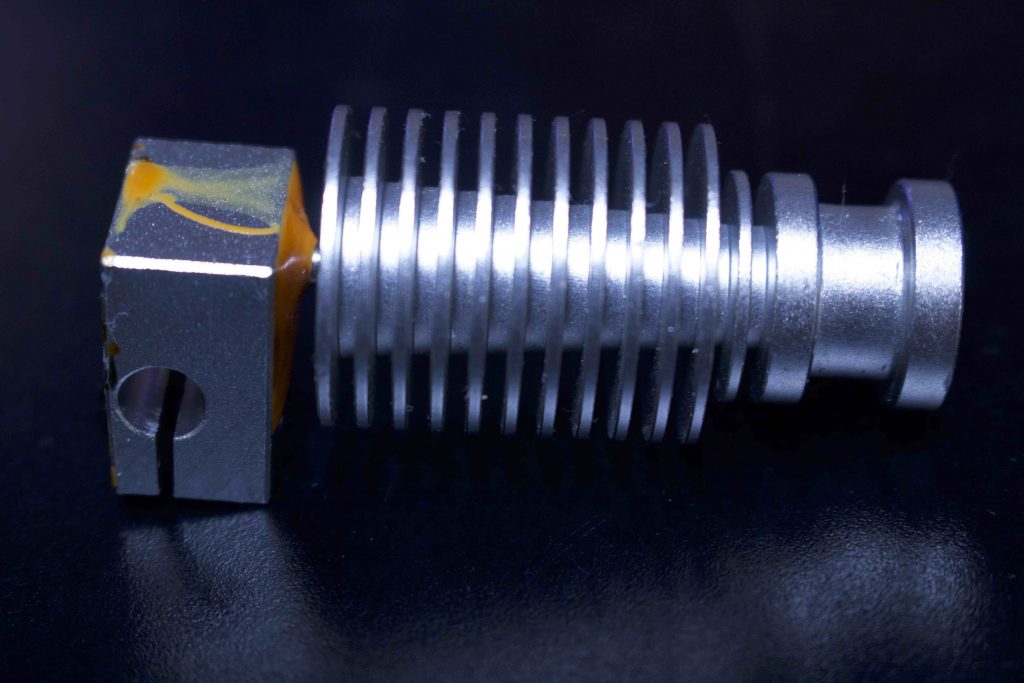

Many pre-assembled 3D-printers, especially cheap Chinese "clones," include all-metal hot ends with a complex, multi-part filament path. What this means is that filament has an opportunity to leak from the joints between these parts. Such as where the threaded heat-break threads into the heater block. This form of construction is usually done to lessen the cost to the manufacturer, but results in headaches for the user, you! Complexity is not always good, and elegance is key when it comes to hot end filament paths.

What To Look For When Buying A Hotend?

When purchasing a new hot end, it is important to examine the design of its filament path. The filament path is the interior part, or parts, of the hot end which contain the filament and guide it from the extruder, through the melt chamber and finally out the nozzle.

The Solution

Hotends.com understands that an elegant, seamless filament paths are the only way to make a hot end leak-proof... and that means more hassle-free printing for you.

Buy a Genuine J-Head and experience the difference of tinker-free, professional 3D-printing today.

Proudly Made In The USA

Proudly Made In The USA