Startup Manufacturing: How 3D Printing Can Help You Bring Your Product to Market

3D printing technology has revolutionized the way products are designed, manufactured, and brought to market. In this article, we will explore how a startup company can use 3D printing to prove out their product, handle low volume sales, and potentially even handle their entire production run. We will also explore the advantages and disadvantages of 3D printing compared to traditional manufacturing methods, the types of 3D printing technologies available, the materials used in 3D printing, 3D printing applications in different industries, the future of 3D printing, and a cost-benefit analysis.

Advantages and Disadvantages of 3D Printing Compared to Traditional Manufacturing Methods:

One of the biggest advantages of 3D printing is its ability to quickly and inexpensively produce prototypes and small batch runs of products. This allows startups to test and refine their designs before committing to expensive injection molding or other traditional manufacturing methods. Additionally, 3D printing can be used to produce end-use products, which eliminates the need for expensive tooling and allows for easy modification of the design. However, 3D printed parts are generally weaker and less durable than parts produced through injection molding.

Types of 3D Printing Technologies:

There are several types of 3D printing technologies available, such as FDM, SLA, and SLS. FDM (Fused Deposition Modeling) uses a filament of thermoplastic material which is melted and extruded to build the object, SLA (Stereolithography) uses a laser to harden a liquid resin to create the object and SLS (Selective Laser Sintering) uses a laser to fuse powdered materials together to create the object. Each technology has its own advantages and disadvantages, and the choice of which to use will depend on the specific application and the properties required for the final product. One key component of FDM technology is the hotend, which controls the flow of the filament and the extrusion temperature. Our company offers high-quality hotends that are compatible with a vast number of FDM/FFF 3D printers.

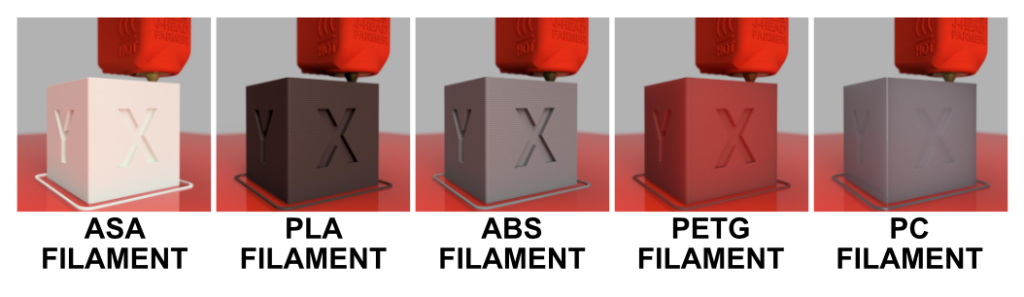

Materials Used in 3D Printing:

3D printing can be used with a variety of materials such as plastics, metals, and ceramics. Each material has its own unique properties such as strength, durability, and cost. It's important for startups to carefully consider which material is best suited for their product and their budget.

3D Printing Applications in Different Industries:

3D printing is being used in a wide range of industries, such as aerospace, healthcare, and automotive. Aerospace is using 3D printing to produce complex, lightweight parts that are difficult to manufacture using traditional methods. In healthcare, 3D printing is being used to create custom prosthetics, implants, and surgical tools. In the automotive industry, 3D printing is being used to produce prototype parts and small batch runs of customized parts.

The Future of 3D Printing:

3D printing technology is constantly evolving, and new advancements are being made all the time. In the future, we can expect to see improvements in print speed, print quality, and material options. Additionally, the use of multi-material printing and multi-color printing is already becoming more prevalent, which will open up new possibilities for product design and customization.

Cost-Benefit Analysis:

When considering the use of 3D printing for product development, small batch production runs, or mass production, it's important to consider the costs involved. The cost of 3D printing technology and materials is constantly decreasing, making it an increasingly viable option for startups. However, it's important to take into account the costs of the equipment, materials, and labor when comparing 3D printing to traditional manufacturing methods.

It's worth noting that 3D printing can be more cost-effective for small batch production runs and prototypes. This is due to the reduced costs associated with tooling and the flexibility of the design process.

However, for high-volume production runs, traditional manufacturing methods such as injection molding may be more cost-effective. It's important for startups to carefully consider the volume of products they plan to produce and weigh the costs and benefits of each manufacturing method.

I hope this article has helped and if you made it this far I commend you!

Proudly Made In The USA

Proudly Made In The USA