Get Spare PTC Fittings For Your Bowden Tube: Or?

Surely there is a better solution?

Bowden PTC fittings, or push-to-connect fittings, are commonly used in 3D printing setups to connect Bowden tubes. While they may seem like a convenient and cost-effective solution, they are prone to several issues that will impact the quality and reliability of your 3D prints.

Bowden Fitting Broken Teeth:

One common issue with PTC fittings is the metal teeth in PTC fittings can break over time due to the constant flexing that occurs during normal 3D printing. This can lead to failed prints and the need for frequent replacements of the fittings. This can be frustrating for users, as it requires frequent adjustments and replacements of the fittings

Bowden Aglet:

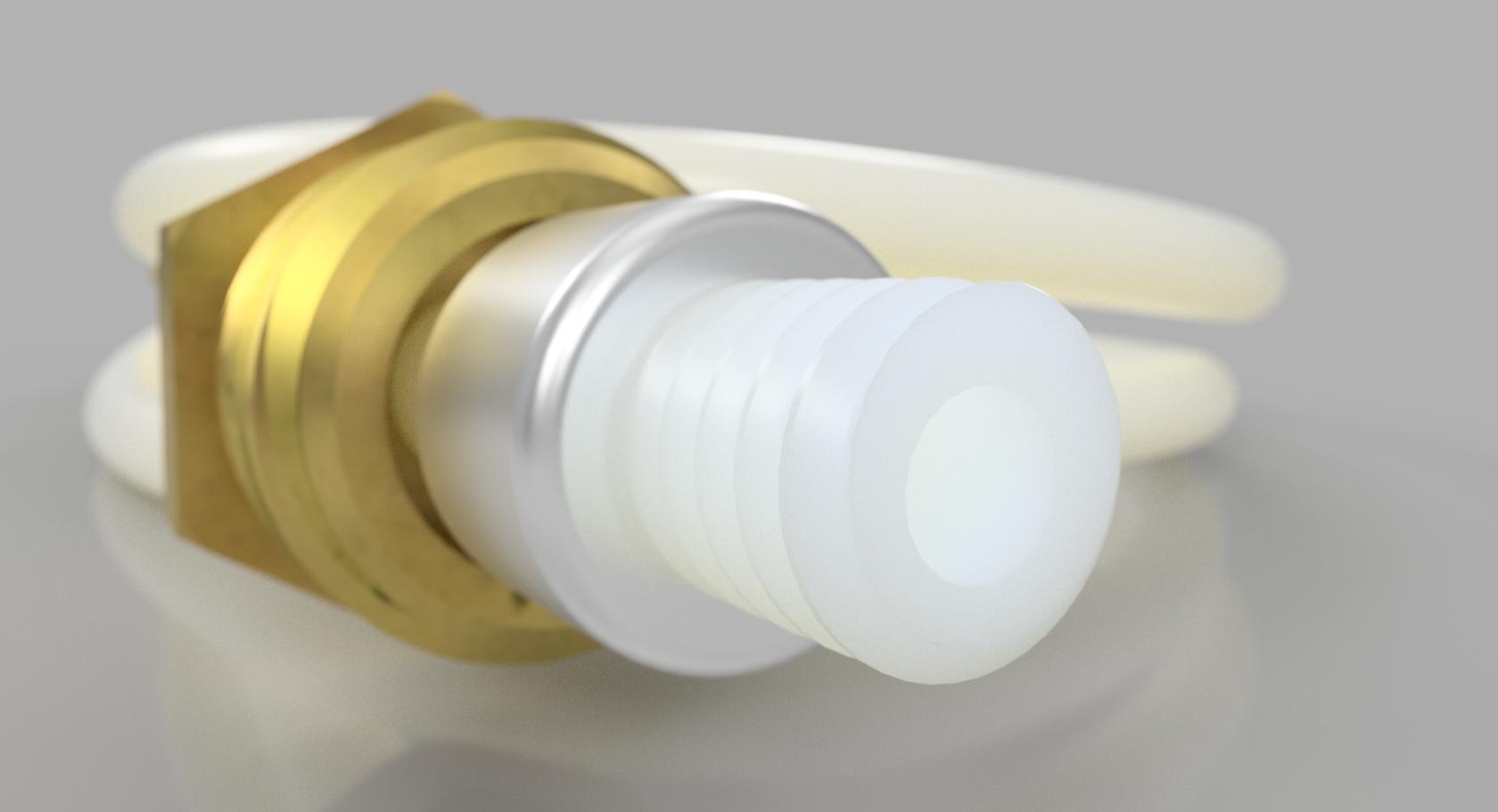

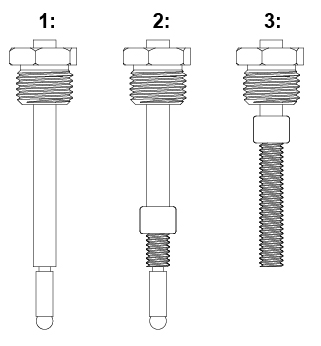

Hotends.com's Bowden Aglet™ is a new product that aims to solve these issues with PTC fittings. The Aglet™ is a self-retaining fitting that eliminates the need for additional retaining rings or clips.

It is designed to be a quality product and users can expect it to last for the lifetime of their 3D printer.

Benefits:

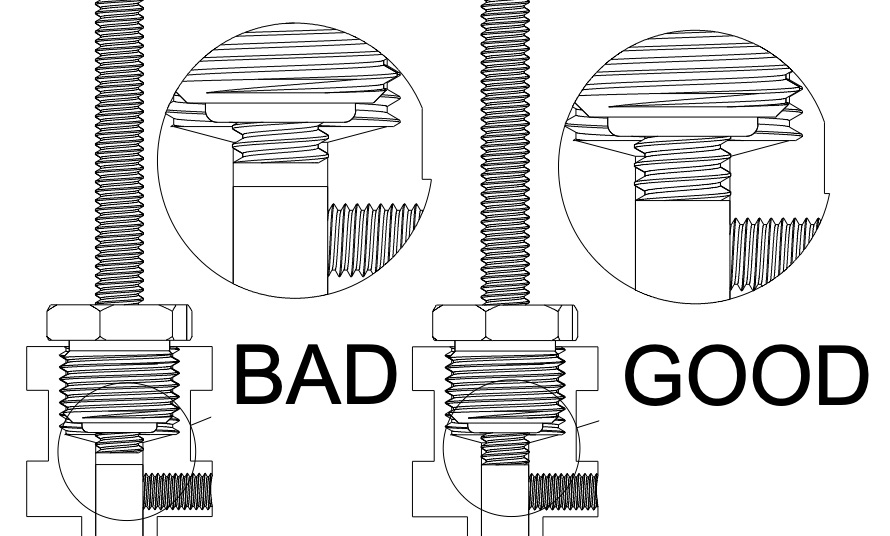

One of the key benefits of the Bowden Aglet™ is its zero backlash design, which ensures that the Bowden tube does not move up and down within the fitting but it still allows for 360 degree rotation.

This greatly improves the accuracy of retractions and ultimately the quality of 3D prints.

Advantages:

Another advantage of the Bowden Aglet™ is that it requires no additional maintenance or adjustments. Once it is installed, users can expect it to function smoothly and consistently without the need for frequent adjustments or replacements.

This can save users time and money in the long run, as they will not need to constantly purchase new PTC fittings.

Overall, the Hotends.com Bowden Aglet™ is a reliable and innovative solution for addressing the issues with PTC fittings in 3D printing setups. It's zero backlash design and quality construction make it a strong choice for users looking to improve the accuracy and reliability of their 3D prints. Ditch the constant hassle of dealing with PTC fittings and try the Bowden Aglet™ today for a smoother and more reliable 3D printing experience.

Who Is Behind The Bowden Aglet?

Hi, my name is Nick Stratton. Owner of Hotends.com and I created the Bowden Aglet™ after getting tired of blowing through PTC fittings one after the other.

I hope you enjoy your Bowden Aglet and help spread the word.

The PTC fittings adopted by the 3D Printing world were originally for pneumatic air lines and are not designed for the use case we put them through in 3D Printing.

They fail due to the constant retractions sometimes getting into the tens of thousands during a print causing the little metal teeth inside to flex and work harden and then break.

Furthermore, the Bowden tube is able to move vertically during retraction, which causes the printer to be unaware of the precise location of the filament. This lack of knowledge can lead to the collapse of the entire system and the Bowden Aglet™ fixes this entirely!

-

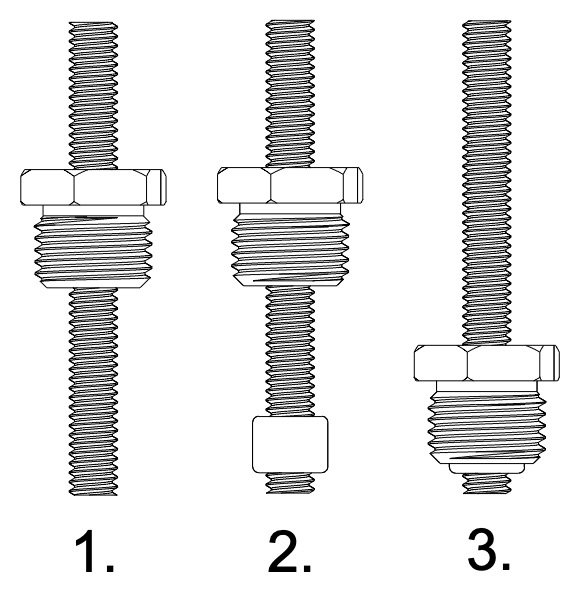

Bowden Aglet Kit With Reducer - M6$25.00

Bowden Aglet Kit With Reducer - M6$25.00 -

Bowden Aglet™ - Preassembled$19.99

Bowden Aglet™ - Preassembled$19.99 -

Bowden Aglet™ kit$12.99

Bowden Aglet™ kit$12.99

Proudly Made In The USA

Proudly Made In The USA