How To Pick Hotend Voltage: 12 Volt vs 24 Volt?

What is the difference between 12 and 24 volt 3D printers?

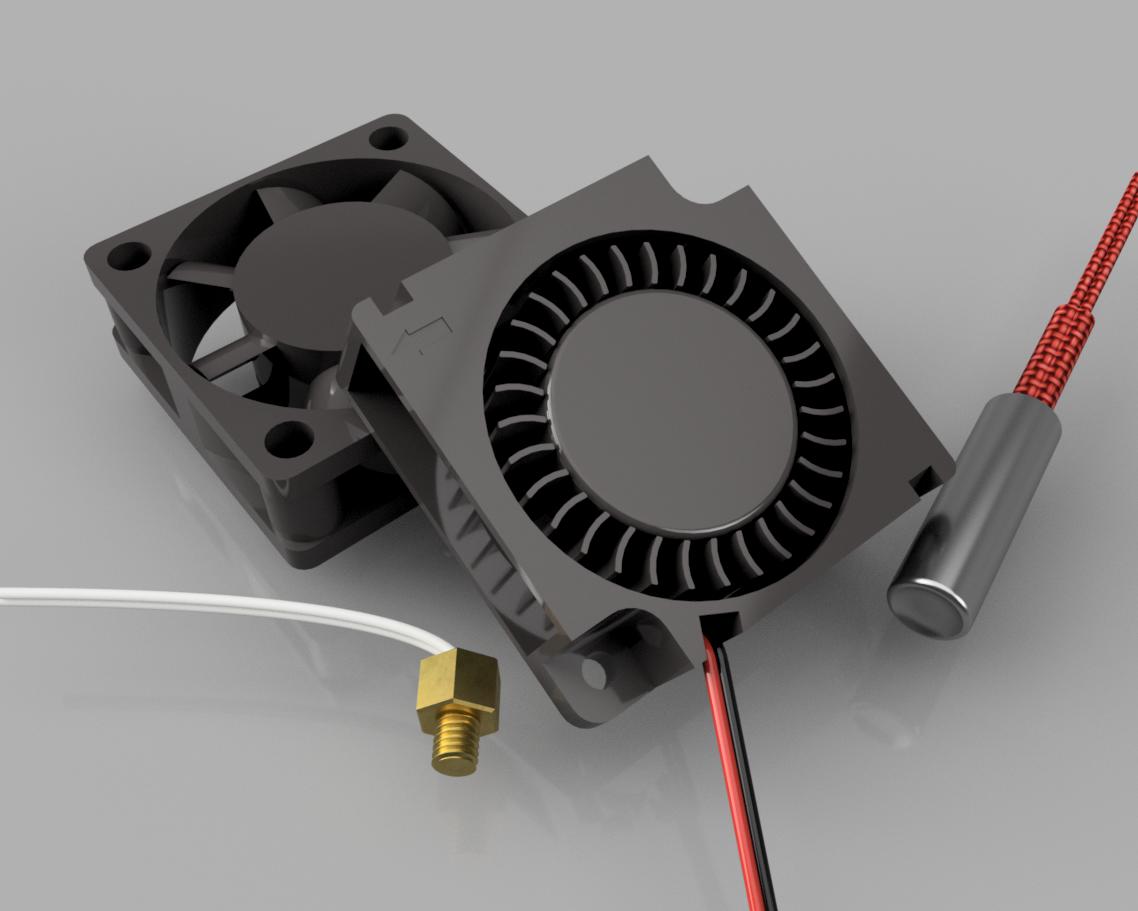

Picking the right voltage for your 3D printer's hotend is an important consideration that can impact the performance and efficiency of your machine. In general, 24V systems tend to offer several advantages over 12V systems, including faster heating and improved stepper motor performance. Here's a closer look at some of the key factors to consider when deciding between a 12V vs 24V hotend.

Ohm's Law

Ohm's Law is a fundamental principle in electrical engineering that states the relationship between voltage, current, and resistance. It can be expressed as:

V = I * R

Where V is the voltage (measured in volts), I is the current (measured in amperes), and R is the resistance (measured in ohms).

Georg Simon Ohm was a German physicist who formulated Ohm's law, a fundamental relationship in physics that describes the relationship between electric current, voltage, and resistance. He published his findings in his 1827 book "The Galvanic Circuit Investigated Mathematically." Ohm's law is widely used in electrical engineering and is a cornerstone of the study of electrical circuits.

In the context of a 3D printer's hotend, Ohm's Law tells us that the voltage applied to the hotend will determine the amount of current that flows through it, and that current will be resisted by the hotend's resistance. So, if we want to increase the current (and therefore the heating) of a hotend, we need to either increase the voltage or decrease the resistance.

24V vs. 12V

When it comes to 3D printer hotends, there are two main voltage options to consider: 12V and 24V. Here's a quick comparison of some of the key differences between these two options:

- Thinner wire: Because 24V systems provide twice the voltage of 12V systems, they can use thinner wire for the same level of current. This can be especially important for 3D printers, where space is often at a premium and thicker wire can take up valuable real estate and thinner wires do weigh less for those chasing speed.

- Faster heating: In general, 24V hotends will heat up faster than 12V hotends due to the higher voltage. Extrapolate this factor across the hundreds of 3d prints you do and think about the time savings where faster heating can help reduce overall print time.

- Improved stepper motor performance: Stepper motors, which are used to drive the motion of 3D printers, tend to work better on 24V systems. This is because higher voltages can provide more torque, which can help improve the positional accuracy and reliability of the printer. (who doesn't want that!)

- Faster heating of DC heat beds: If your 3D printer uses a DC heat bed (as opposed to an AC heat bed), it will heat up faster on a 24V system. This is because the higher voltage allows more current to flow through the bed, resulting in faster heating.

Overall, if you have a choice, 24V systems tend to be the better option for 3D printer builds. However, it's worth noting that hotends.com offers both 12V and 24V hotends, heater cartridges, and fans, so you can choose the option that best fits your needs.

Proudly Made In The USA

Proudly Made In The USA