How 3D printing is revolutionizing the manufacturing industry

3D printing is changing the game for manufacturers all over the world. This amazing technology, also known as additive manufacturing, allows businesses to create complex, custom designs quickly and affordably. And trust me, it's a game-changer.

Let's start with the basics.

With traditional manufacturing methods, companies often have to spend a ton of time and money on creating molds and tooling. This can take weeks or even months, which can be a huge pain. But with 3D printing, designers can create and test prototypes in just a few hours. Talk about a time-saver!

Another cool thing about 3D printing is its flexibility.

Traditional manufacturing is limited to a few materials, but 3D printing can use a wide range of materials, from plastics and metals to ceramics and biomaterials. This means manufacturers can create products with unique properties and functionality, which opens up all sorts of possibilities for innovation.

3D printing is also super eco-friendly.

Traditional manufacturing generates a ton of waste, which can be expensive to dispose of and harmful to the environment. With 3D printing, the material is added layer by layer called Stereolithography, so there's very little waste. This not only saves money and resources but also reduces the environmental impact of manufacturing.

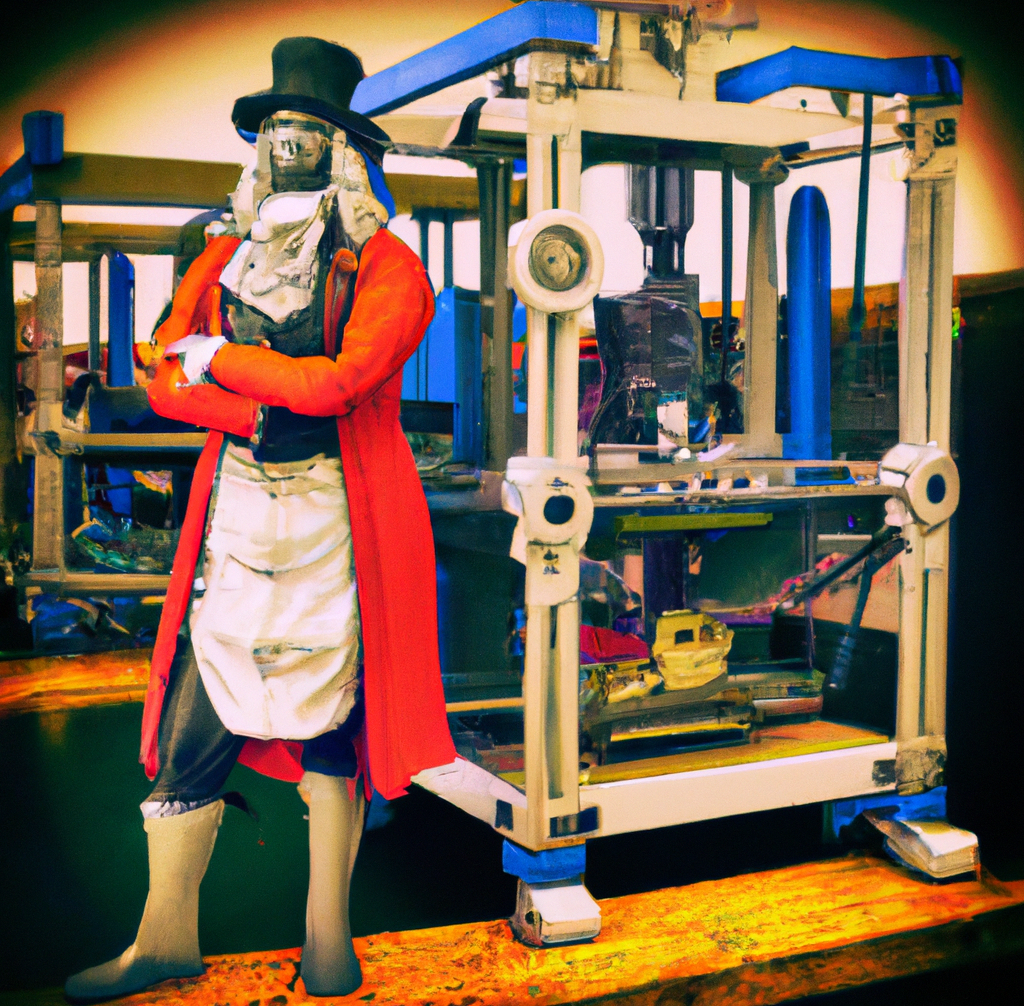

Create - Customize - Mass Produce

One of the most exciting things about 3D printing is its potential to create customized, mass-produced products by way of 3D Print Farms. In the past, mass production relied on standardized designs that were difficult and expensive to alter. But with 3D printing, manufacturers can easily produce custom products on demand, without the need for expensive tooling. This has the potential to greatly increase the flexibility and efficiency of manufacturing operations.

In short, 3D printing is a game-changer for the manufacturing industry. It allows businesses to create complex, custom designs quickly and affordably, and its flexibility and eco-friendliness make it a valuable tool for manufacturers. As the technology continues to advance, we can expect to see even more amazing developments and applications in the manufacturing world.

Proudly Made In The USA

Proudly Made In The USA