Login

Eliminate stringing on 3D prints: A step-by-step guide

4 min read

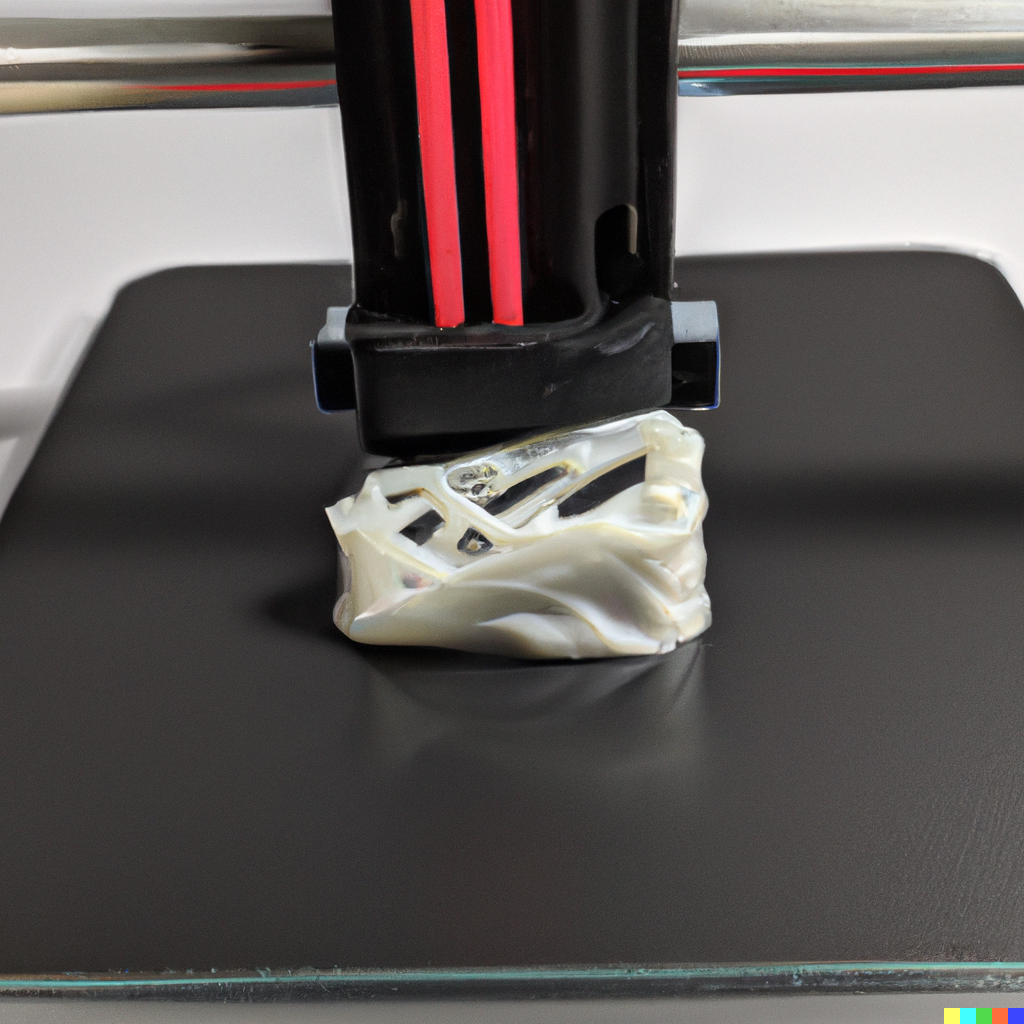

Stringing, also known as oozing, is a common issue in 3D printing that occurs when plastic filament is extruded from the nozzle of a 3D printer even when the printer is not actively printing. This results in strings of plastic being left behind on the print, which can ruin the appearance of the finished product and make it difficult to clean.

Fortunately, there are several steps you can take to eliminate stringing on your 3D prints and achieve a clean, professional-looking result. In this article, we'll walk you through each of these steps in detail, so you can get started improving your 3D printing experience right away.

Step By Step Guide: #

Eliminate Stringing On 3D Prints:

- Adjust the retraction settings on your 3D printer

Retraction settings control how much the filament is pulled back into the nozzle before a new section of the print is started. When the retraction distance is set too low, the filament may not be pulled back far enough, leading to stringing. By adjusting the retraction settings, you can reduce the amount of filament that is left behind as the nozzle moves, which can help reduce or eliminate stringing on your 3D prints.

By increasing the retraction distance and/or retraction speed, you can pull the filament back into the nozzle more effectively, which can help reduce or eliminate stringing. This can result in smoother, more detailed prints with a professional finish. It is important to experiment with different retraction settings to find the optimal settings for your particular printer and filament. - Use a layer cooling fan

A cooling fan is a common accessory used with 3D printers. It is typically mounted near the nozzle and is used to blow cool air onto the extruded filament as it is printed. This helps to solidify the filament more quickly, reducing the chances of stringing.

When a 3D printer is printing a complex model, the nozzle must move quickly and make sharp turns in order to create the desired shape. As the nozzle moves, it can leave behind a thin strand of melted filament, known as "stringing". This can result in a messy-looking print.

By using a cooling fan, the extruded filament is cooled more quickly, which helps to solidify it and prevent stringing. The cooling fan also helps to reduce warping and improve the overall quality of the print.

So, using a cooling fan can help eliminate stringing on 3D prints by quickly cooling the extruded filament, which allows it to solidify more quickly and prevents stringing. This can result in smoother, more detailed prints with a professional finish. - Adjust the printing temperature

The print temperature is an important setting that affects the flow of the filament as it is extruded. By adjusting the print temperature, you can improve the flow of the filament and reduce the chances of stringing.

In general, the print temperature should be set to the recommended temperature for the type of filament you are using. This information is typically provided by the filament manufacturer and can be found on the packaging or in the documentation.

By increasing or decreasing the print temperature, you can improve the flow of the filament, which can help to reduce or eliminate stringing. However, it is important to be careful not to set the temperature too high, as this can cause other problems, as well as printing too low causes problems in the other direction.

Adjusting the temperature 5 degrees at a time is usually sufficient. - Slow Down The Print Speed

Slowing down the print speed can help reduce stringing on 3D prints. When the print speed is too fast, the filament may not have enough time to cool and solidify before the nozzle moves to the next location. This can result in stringing, where a thin strand of melted filament is left behind.

By slowing down the print speed, you can give the filament more time to cool and solidify, which can help reduce or eliminate stringing. This can result in smoother, more detailed prints with a high quality finish.

It is important to experiment with different print speeds to find the optimal settings for your particular printer and filament. In general, slower print speeds are better for reducing stringing, but they will also result in longer print times. It is a trade-off that you will need to consider when setting your print speed.

Conclusion #

By following these steps, you can eliminate stringing on your 3D prints and achieve smoother, more detailed prints. Now get out there and start printing better!

Powered by BetterDocs

Proudly Made In The USA

Proudly Made In The USA